Chin-Yi Cheng

2017

Project Dreamcatcher

Research Intern Project at Autodesk Design Research, Summer 2015

https://autodeskresearch.com/projects/dreamcatcher

What if a CAD system could automatically generate tens, hundreds, or even thousands of design options that all meet your specified high-level goals? It’s no longer what if: it’s Project Dreamcatcher, and it’s the next generation of computational design.

Dreamcatcher is a goal-directed design (GDD) system that enables designers to input specific design objectives, including functional requirements, material type, manufacturability, performance criteria, and cost restrictions. The infinite computing power of the cloud then takes over.

Interactive Design Prototype

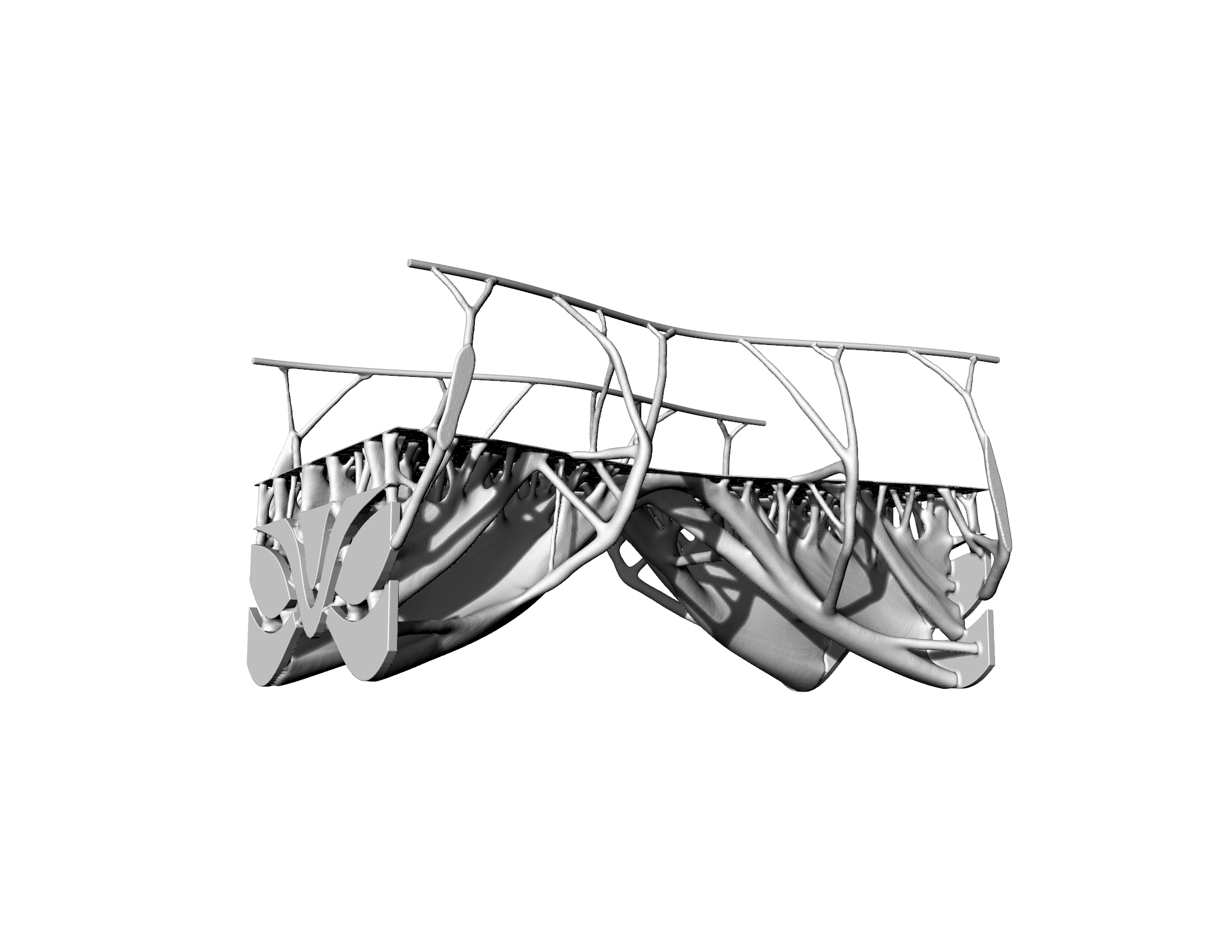

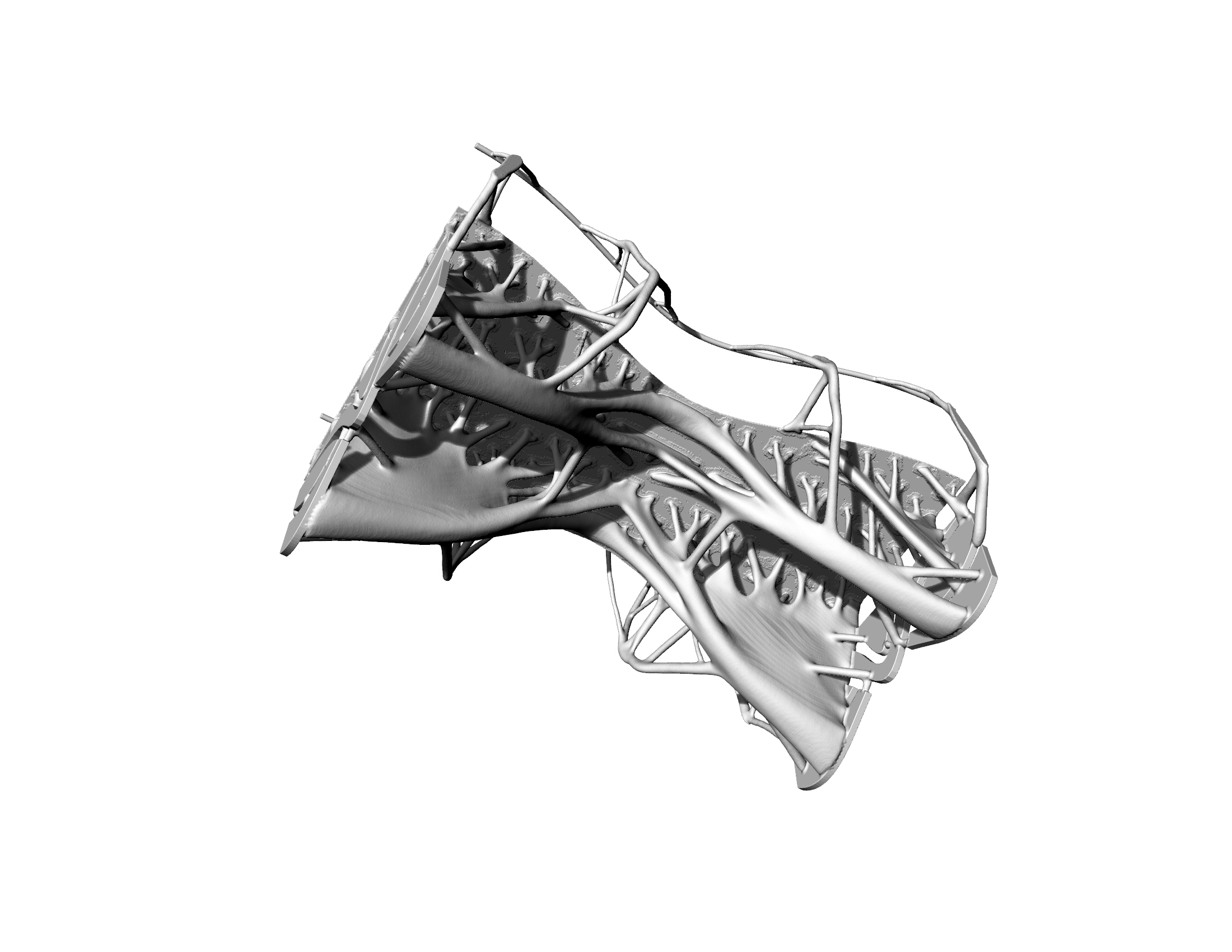

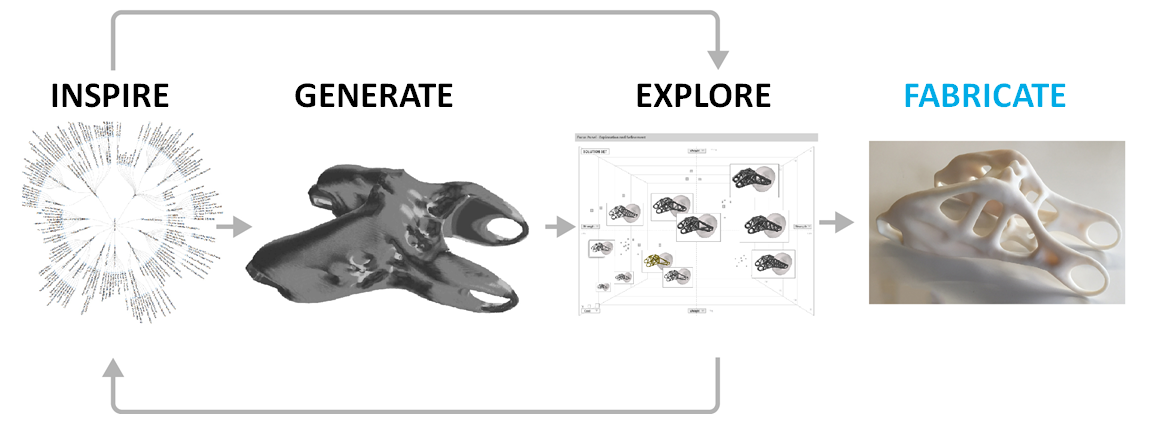

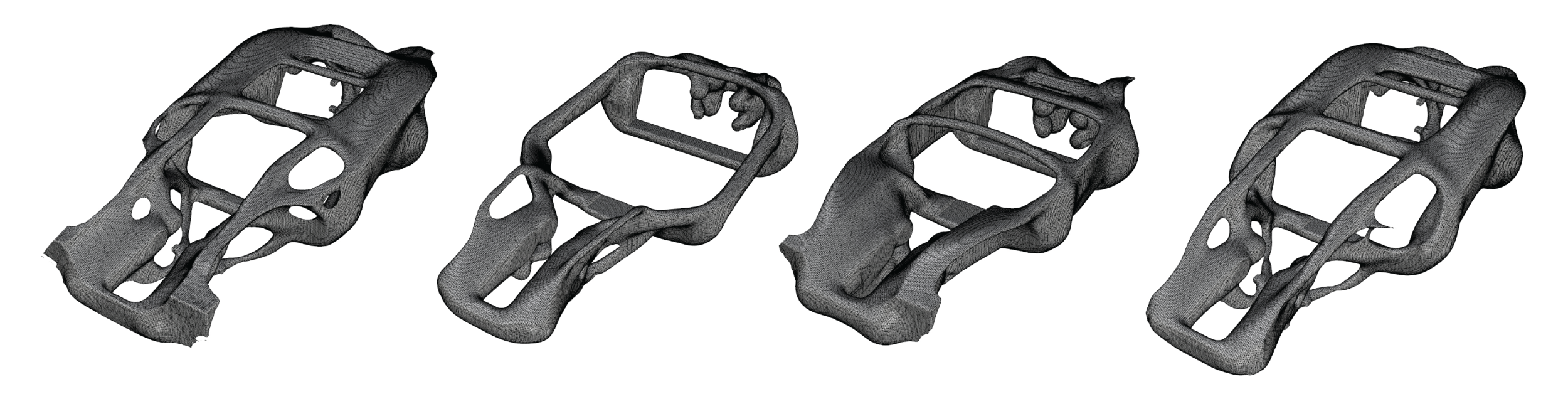

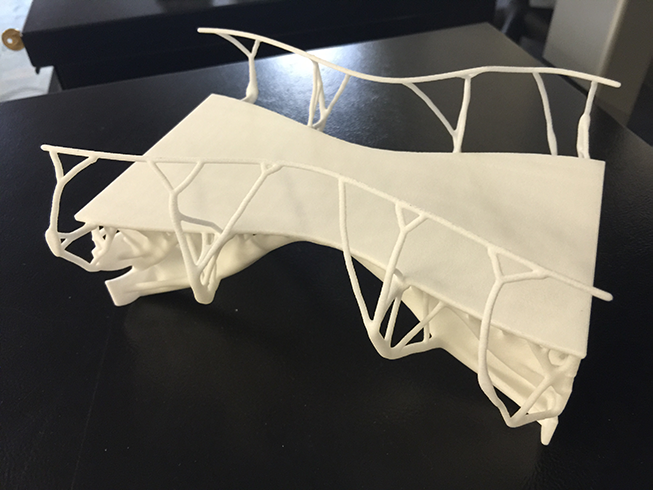

Project Dreamcather is a huge design system including different phases: Inspire, Generate, Explore and Fabricate. The user can set up design requirement and conditions in the Ispire interface, and the system will generate numbers of solutions. Then the use can explore and pick up the best solution from them, and move to the fabrication process.

Photo credit: Autodesk Research

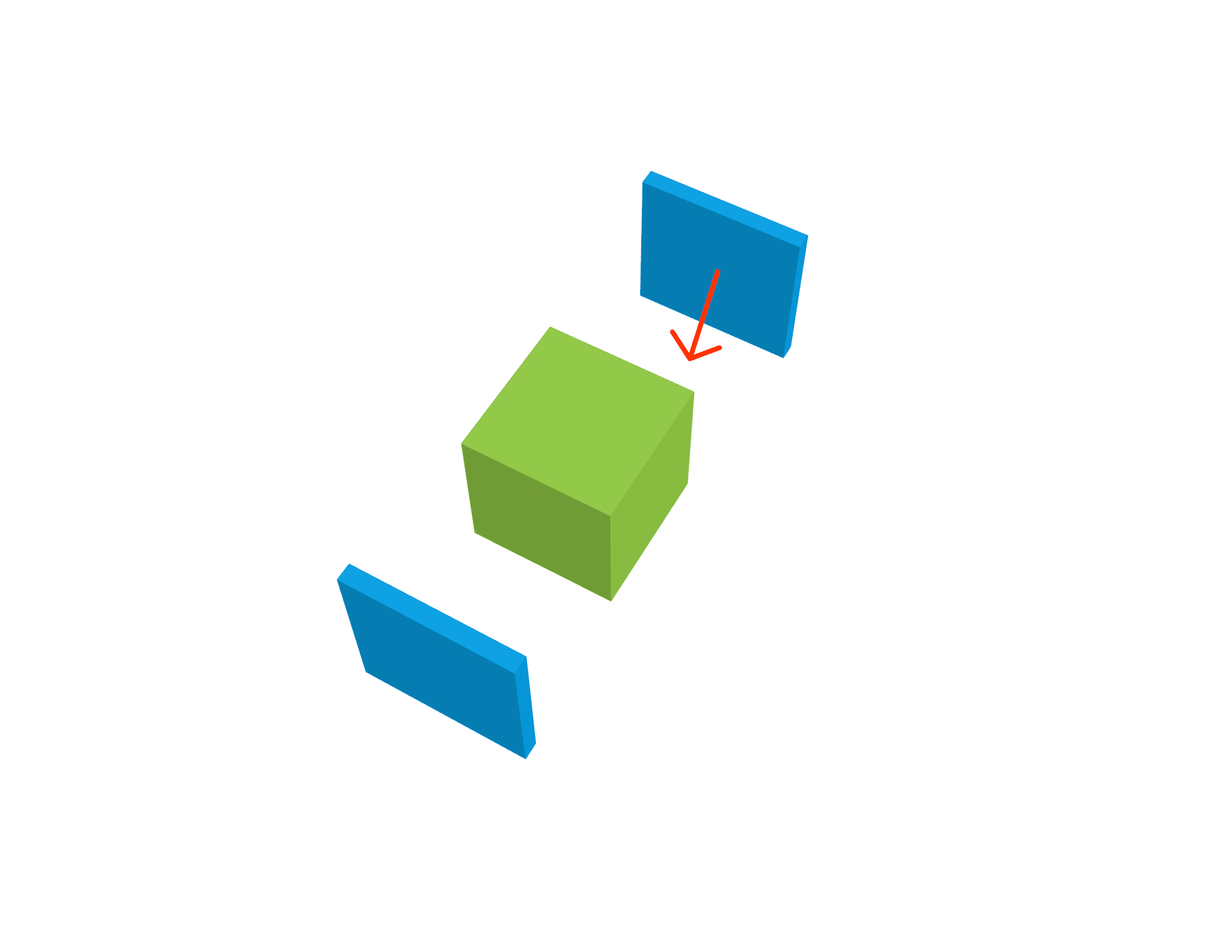

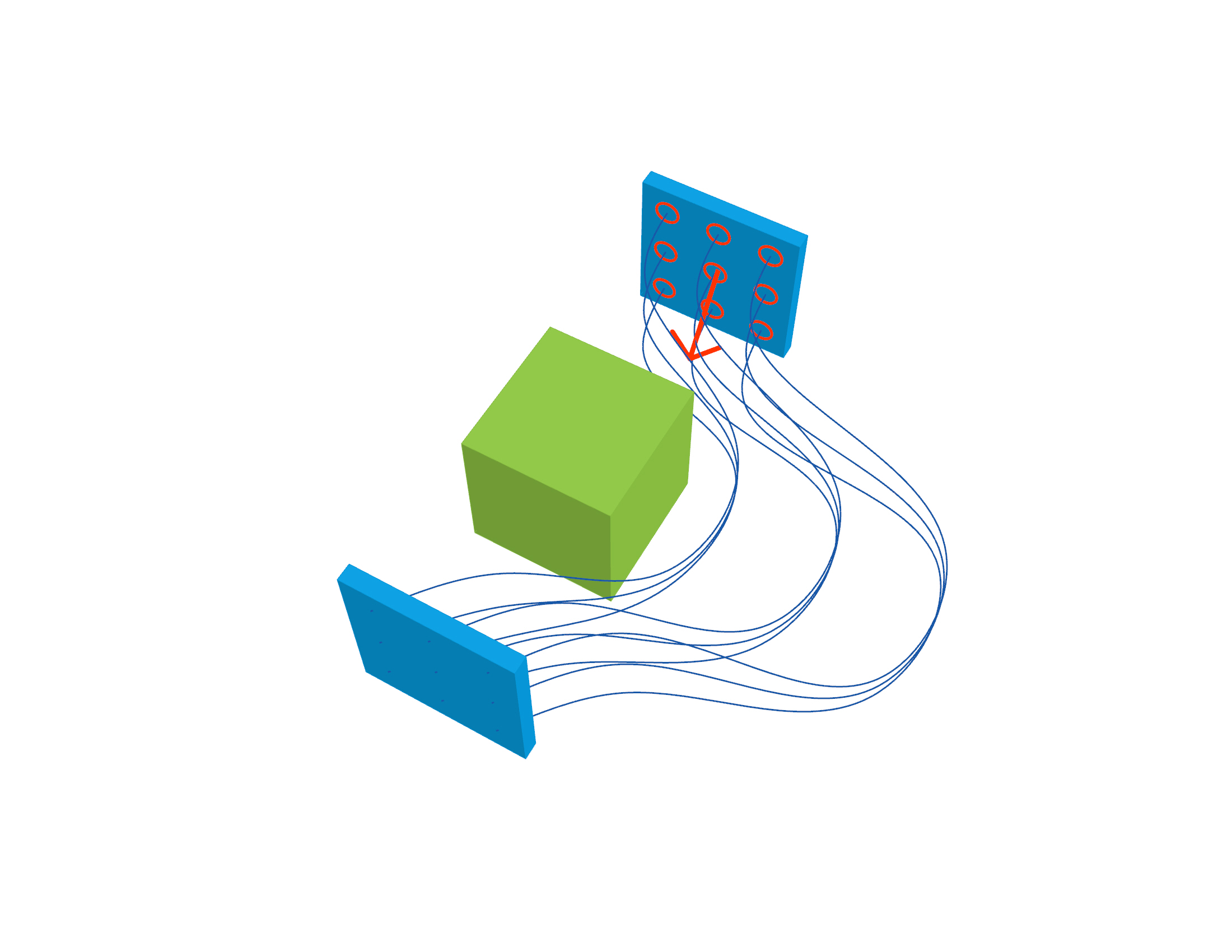

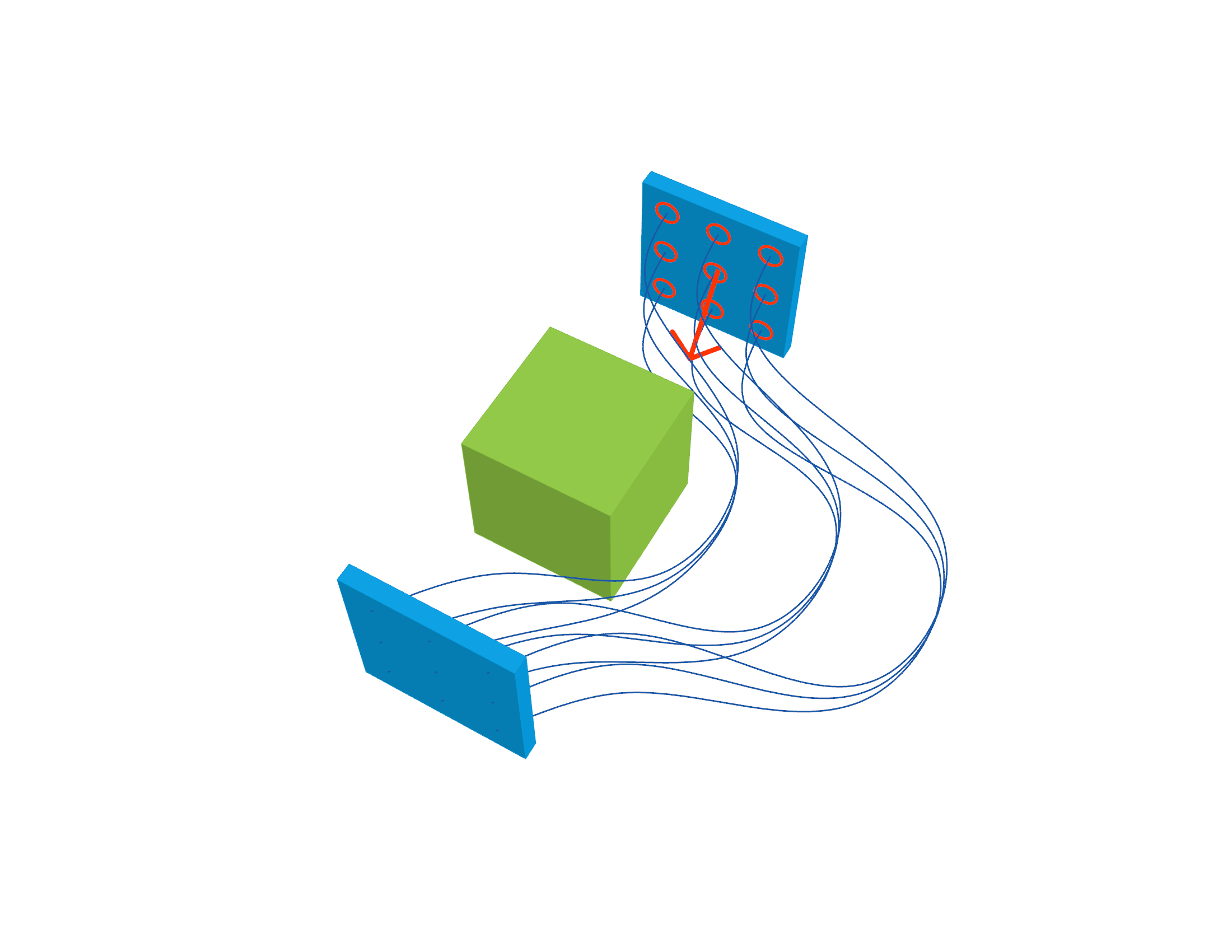

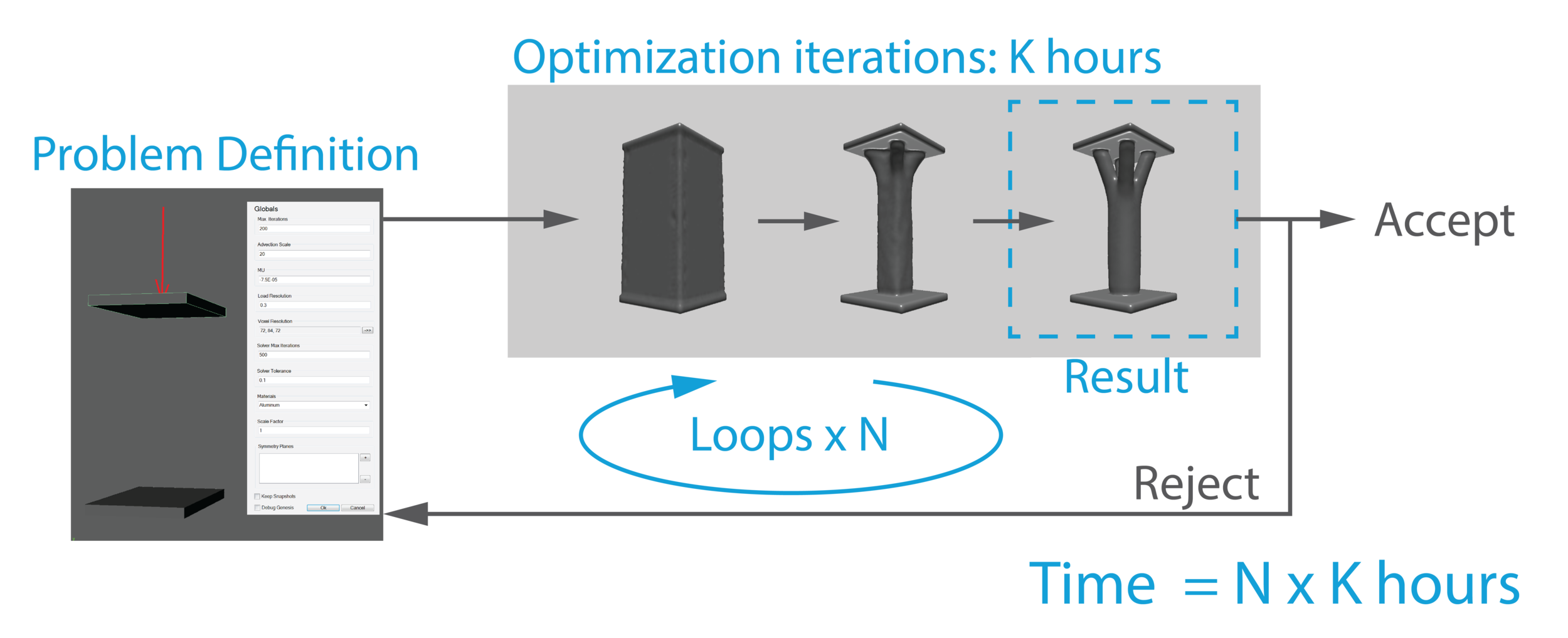

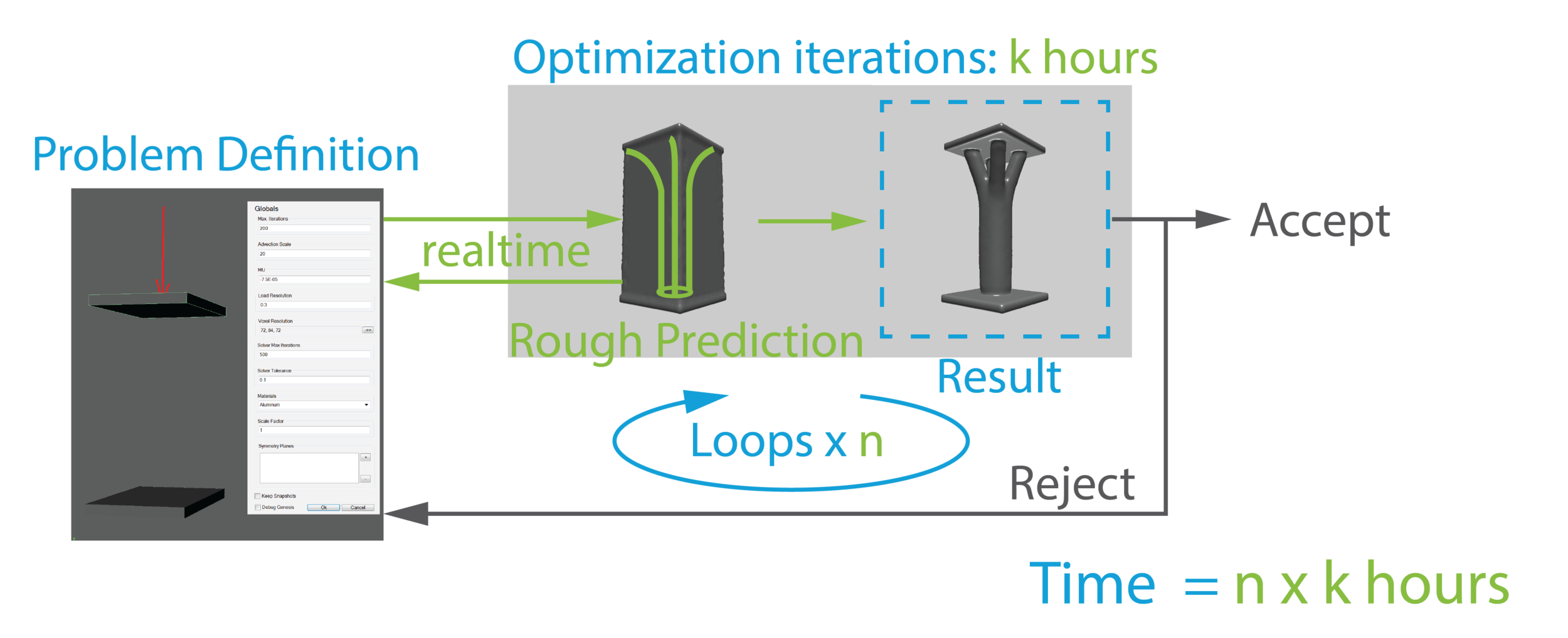

In the internship, I was focusing on bridging the inspire and generate phases together. Some of the design optimization process cannot interact with the user, and the result is simply calculated based on the inputs. Moreover, these optimization algorithm, such as topology optimization, take time to run.

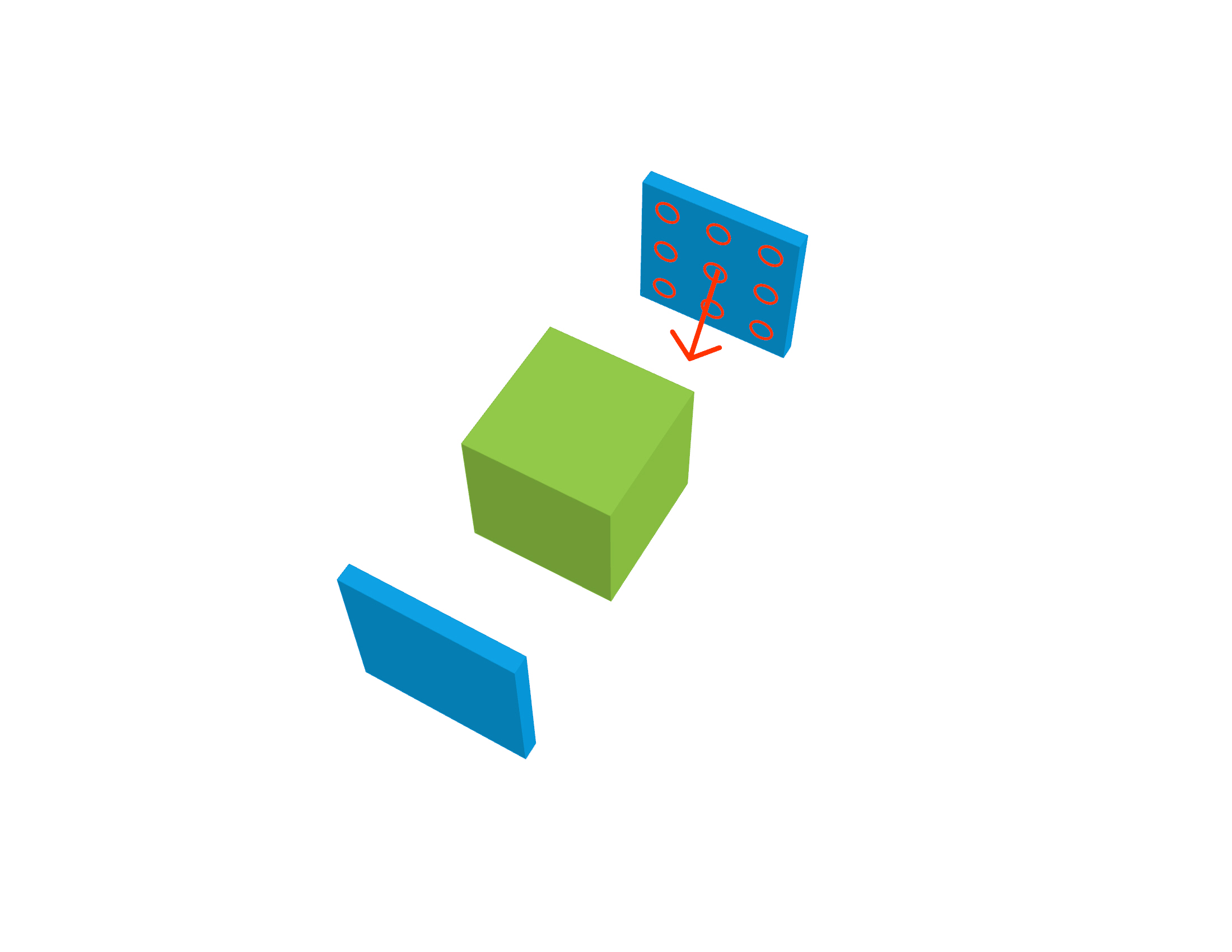

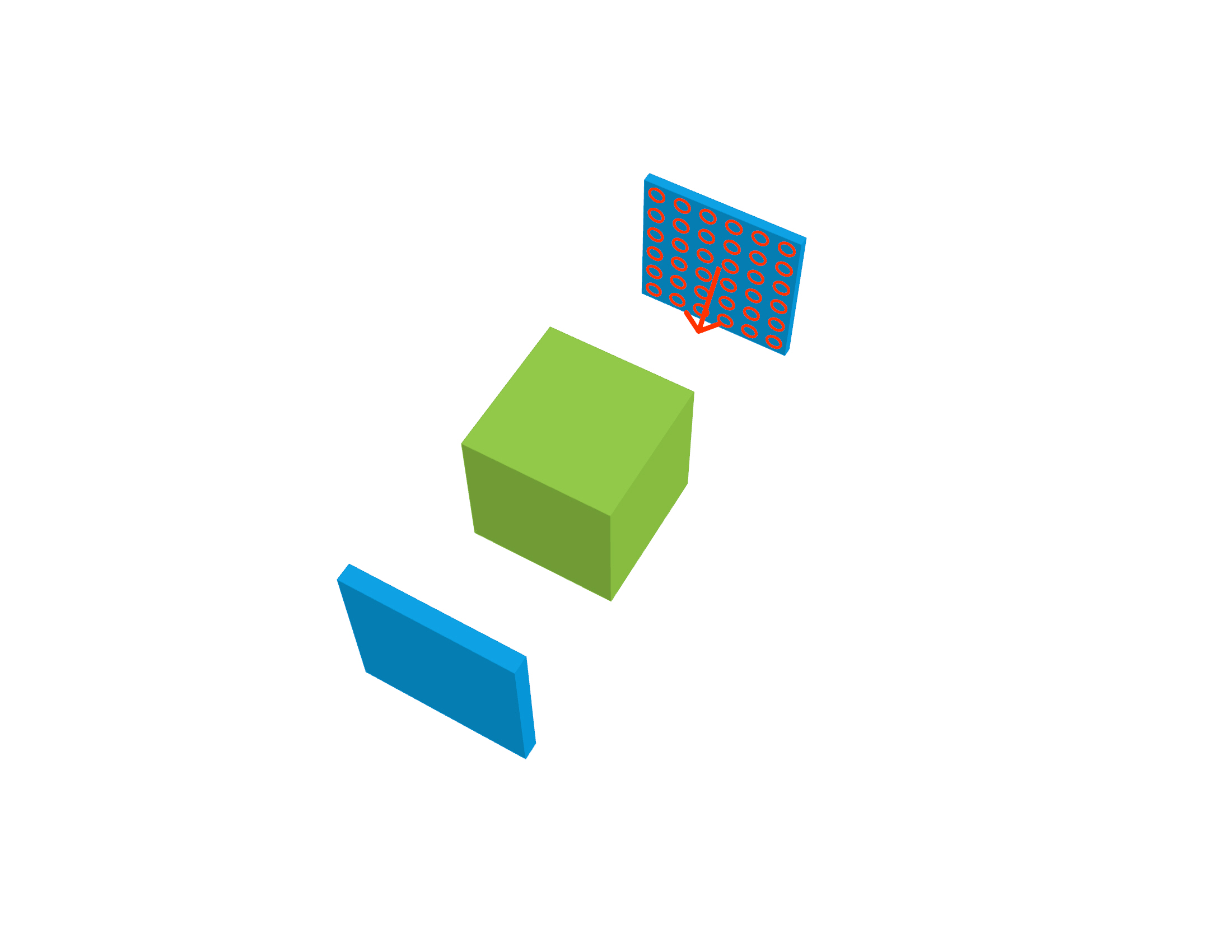

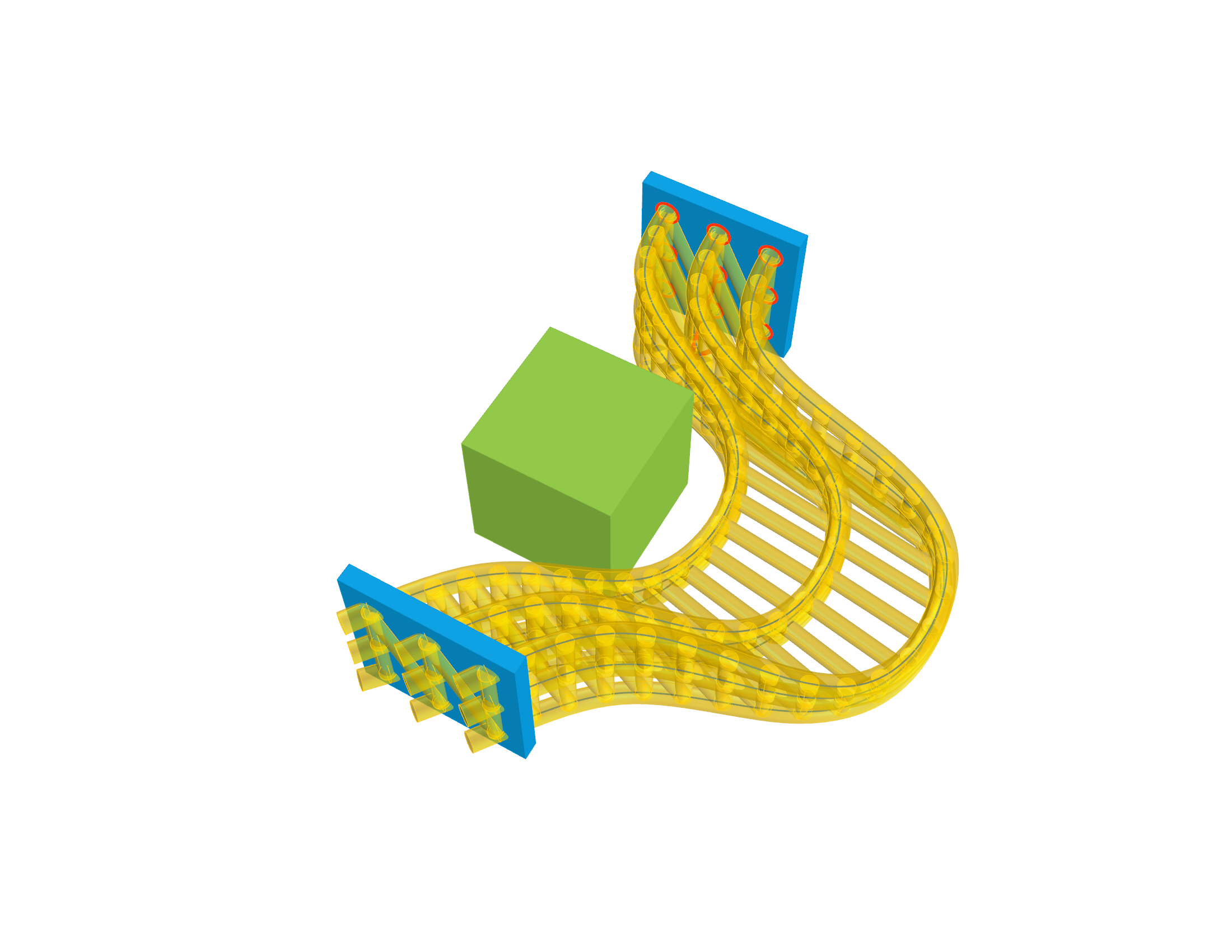

Therefore, I built a prototype to the system which can not only make the process interactive but also speed up the optimization algorithm. The key concept of this prototype is that if we can have a rough prediction before starting the optimization, the user can see what will happen in a rough sense and adjust their input; and the optimization algorithm also can get a better initial status which is closer to the final result.

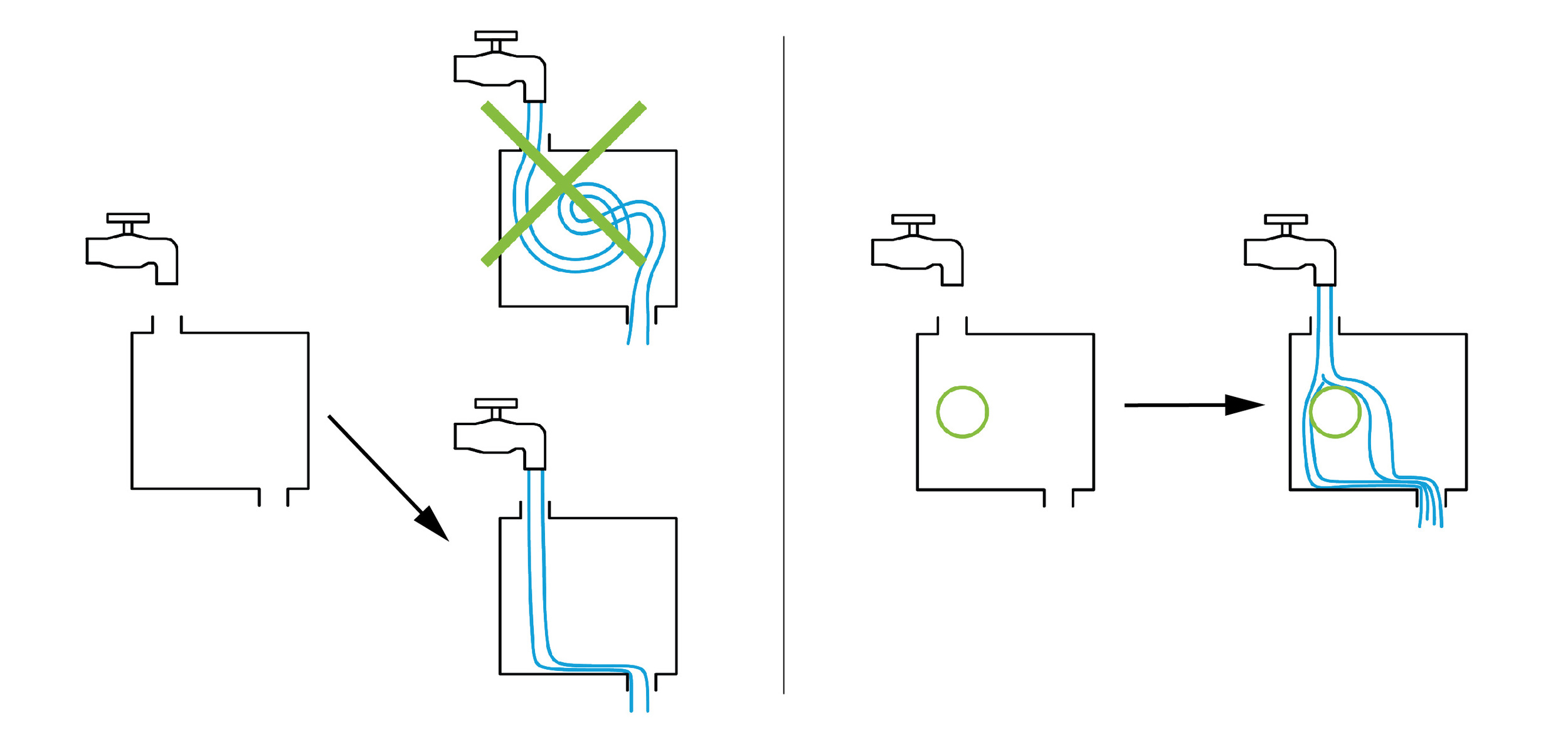

A easy analogy is: given a water tap and a tank, any of us can think roughly the way water flows through the tank. In contrast, the optimization algorithm might not have the "common sense," and therefore it might not be efficient. However, if we record enough data from previous tasks, and adding some simple guideline rules into the system, it will be able to predict, although roughly, before the real task.

Performance Comparison

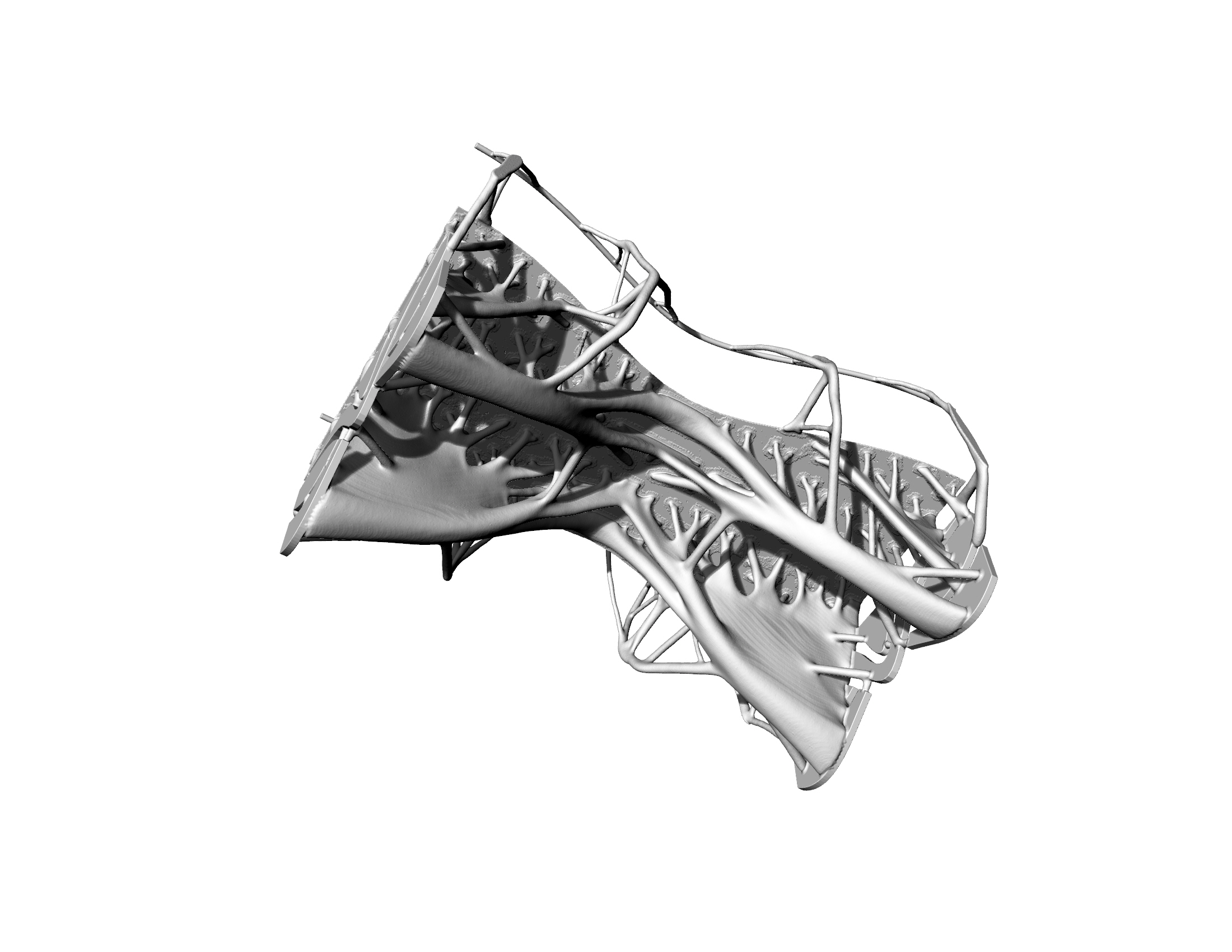

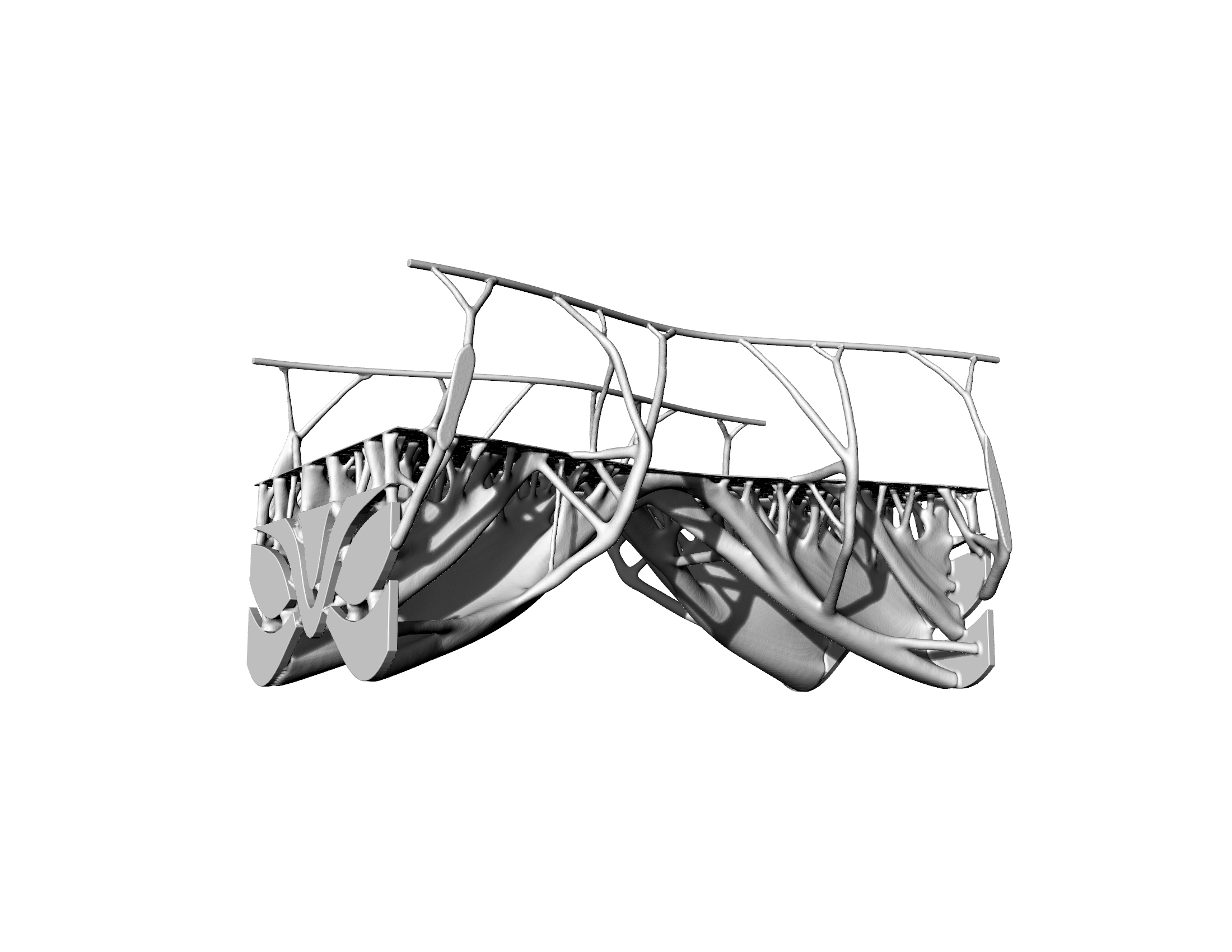

Design Results

We collaborated with customers at Autodesk, such as MX3D, a metal printing startup, helping them design a metal printing bridge in Amsterdam; and Bandito Brothers, a car design company, helping them design a optimized car chassis based on their road test data.